Resource

- Use of over 100 advanced equipments

- Accumulated material technology developed over many years

- Injection / Extrusion molding technology

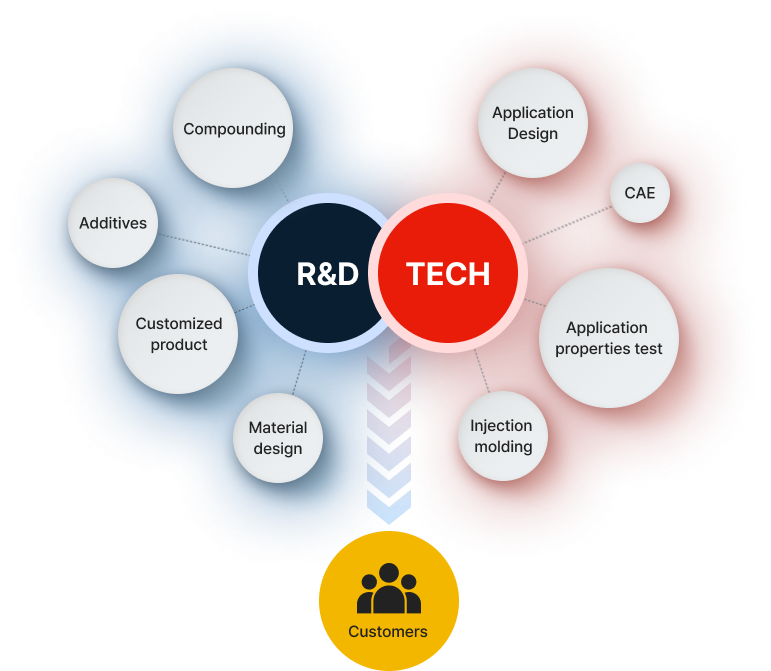

Development

- Creative and practical product development

- Customized product development

- Quality improvement

- High-performance new materials

Tech &CAE

- Specialized technical support services

- Raw material and molded product evaluation support

- Worldwide technical support services

- Product and mold optimization through CAE

Analysis and evaluation spectrum utilizing 140 types of equipment

Providing customer-tailored product development and molded product evaluation support with over 140 types of analysis and testing equipment

-

Material analysis

Material analysis -

Chemical testing

Chemical testing -

Mechanical testing

Mechanical testing -

Heat resistance testing

Heat resistance testing -

Long term testing

Long term testing -

Surface analysis

Surface analysis -

Rheological analysis

Rheological analysis

Customer friendly test system

KPAC's unique customer-friendly system that recommends more verified materials by implementing customer part durability evaluation at the research institute

-

H2, UreaPermeation rete

H2, UreaPermeation rete -

ClipIn-ex force

ClipIn-ex force -

Ball BearingDuration

Ball BearingDuration -

GearCreep behavior

GearCreep behavior -

RollerDuration

RollerDuration -

Extreme temp.Friction & Wear

Extreme temp.Friction & Wear -

Door CheckDuration

Door CheckDuration

Design Solution (CAE)

Injection condition and design optimization support system for customer convenience

-

Injection molding analysis

-

Cool-Fill-Pack-Warp Analysis

Cool-Fill-Pack-Warp Analysis -

Runner balance

Runner balance -

Deflection

Deflection -

Fiber orientation

Fiber orientation -

Gate position

Gate position -

Cooling channel

Cooling channel

-

-

Structural analysis

-

Vibration

Vibration -

Shock/Impact

Shock/Impact -

Optimization

Optimization -

Air bag

Air bag -

Thermal

Thermal

-